Drive the next era of manufacturing

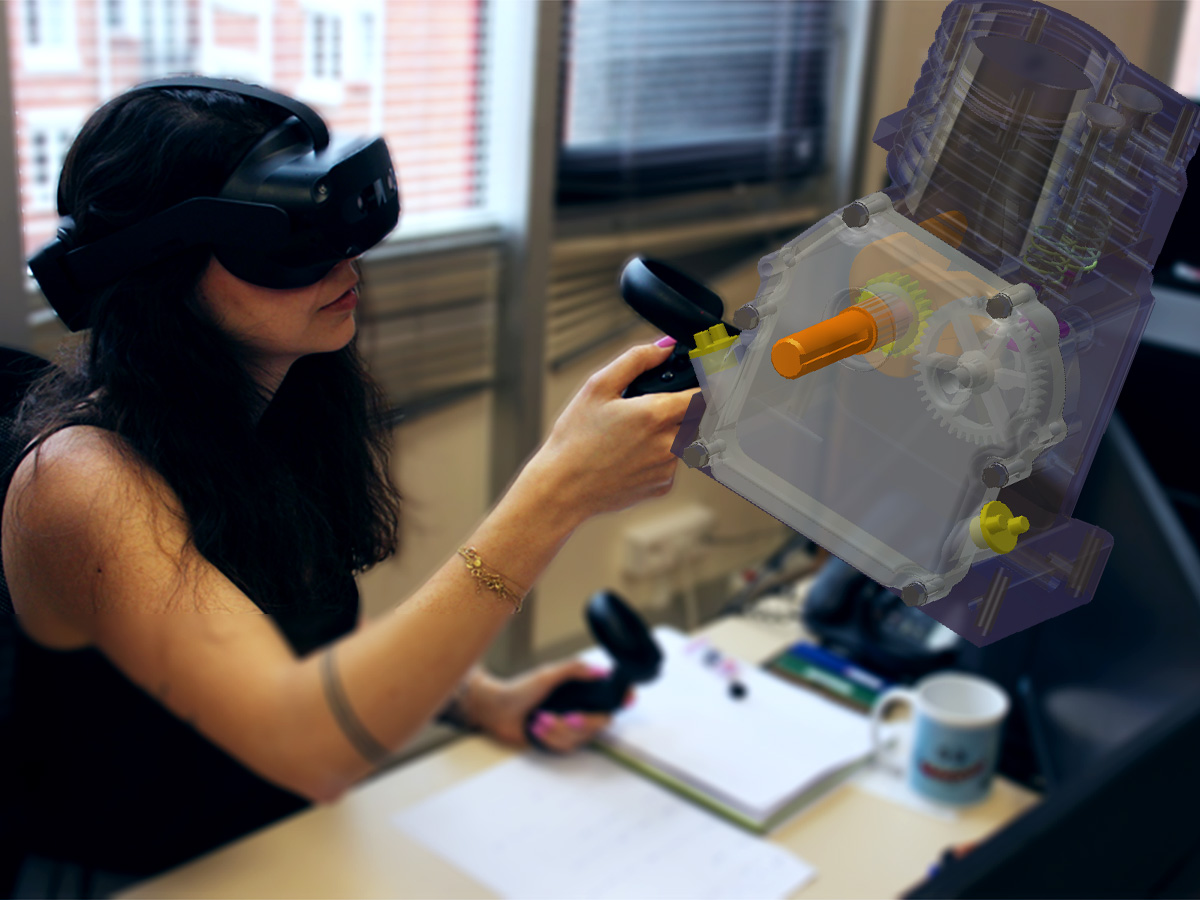

Say goodbye to traditional design-to-manufacturing limitations and hello to a revolutionary solution. With XR for manufacturing, teams collaborate better, leading to more cost-effective processes and greater competitiveness. XR technology empowers manufacturers to build competitive and enhanced products, thanks to virtual reality, and lay the foundation for Industry 4.0.

Collaboration-fueled manufacturing for unmatched efficiency

Revolutionize the way you approach manufacturing and stay ahead of the competition with better, faster, cheaper innovations. XR technology transform your process with seamless rapid-prototyping in true-to-life 1:1 scale, without the need for data conversion. Collaborate with as many users as necessary in real-time, using any combination of XR hardware and 3D software, for the ultimate competitive edge.

Optimized workflows for smarter manufacturing process

Say goodbye to endless back-and-forth between teams, miscommunication and ineffective manufacturing processes.

Provide your technicians with real-time access to the 3D models of their equipment, and real-like simulations on digital twins of their facilities. Receive the benefits of Industry 4.0 with the ability to access your CAD (Computer-aided design) data anywhere, anytime, and easily replicate local issues or products for an improved workflow.

Higher Quality at Launch with Assembly Simulation

Rev up your assembly process upfront, for more accurate manufacturing plans and improved time-to-volume-production. By leveraging your existing assembly simulation software, such as Siemens PLM Tecnomatix, and adding AR/VR capabilities, you can test mountability with unparalleled accuracy, paving the way for a more efficient production process. Avoid lengthy planning phases and deliver higher quality at launch.

Manufacturing better with TechViz

Here is an example of workstation ergonomics with TechViz. Find out how GMI optimized mining and drilling thanks to our intuitive virtual reality solution.

Better-trained specialists and technicians for remote maintenance and assistance

Transform your maintenance process with the power of XR technology and solve even the toughest challenges. Using specialized training – with VR headsets or immersive rooms – you can replicate dangerous or expensive scenarios in a controlled environment. No more unprepared factories during downtime or costly delays waiting for specialists from around the world. Embrace efficiency and cost savings in manufacturing with XR technology.

Advanced factory layout planning for ergonomic and efficient facilities

Experience a smarter, faster and more precise approach to designing your facility, with the ability to explore and test at full scale multiple configurations designed with your regular process planning application, such as Hexagon Intergraph SmartPlant or Siemens PLM Process Simulate. With XR technology, you can run a simulation and validate all your ideas for ergonomic, safe and optimized floor plans in a real-life, immersive environment before a single piece of equipment is moved.

One-click from CAD to VR

Load your model in its native CAD application

Select the software to display with TechViz

Instantly navigate in your 3D model in VR

« Key factors are time, quality, and cost ». « Virtual reality helps prevent failure analysis in a product design for a guaranty of quality. We carry out virtual photorealistic design reviews in real time to save time. Virtual prototypes are now replacing physical prototypes to reduce costs and to improve on efficiency with faster delivery of digital prototypes to required locations ».

– Markus Halbritter, Senior Project Manager, Virtual Reality and 3D Visualization, at BSH Boschund Siemens Hausgeräte GmbH

Unlock your manufacturing potential with TechViz

Works with any XR system

Visualize 3D models from 200+ CAD software with VR headsets, powerwalls, or immersive rooms.

No data conversion

Enjoy a seamless XR experience with no risks of losing data quality or accuracy, even with large-scale models

Top level security

Keep your 3D data safe in all situations – even with remote collaborators. Only position data is exchanged between participants.

Wide range of features

Work smarter with cutting-edge tools with virtual review tools, collaboration tools and integrate the human factor in your process.

We helped them with their AR/VR projects

XR in manufacturing according to TechViz

What is XR?

XR (eXtended Reality) is an umbrella term that refers to augmented reality (AR), virtual reality (VR) and mixed reality (MR). XR technology either by immerse you in the computer-generated virtual environment, add to, or augment, the user’s surroundings, or both of those.

Is XR right for my company?

XR provides an innovative edge to many organizations, but it might not be suitable for every product or every business. In many use cases, Augmented and Virtual technology will optimize existing processes and open new opportunities. For an XR solution to be profitable, you need to understand how XR technology operates, and what your current design-to-market process is.

Feel free to contact our experts to find out if XR can be a solution for your own use cases.

What does XR mean in manufacturing?

There are many use cases involving XR and manufacturing, from the design-to-production. Real-life application of XR in manufacturing include digital prototyping and production development, process improvement, effective collaboration, ergonomics analysis, faster maintenance and safer training environments.

How do I choose a XR solution? How much will it cost?

There are several Augmented and Virtual software on the market, and each application has the same major function. However, most of them specialize in an industry and/or are compatible with a narrow choice of CAD program. Also, many AR/VR software convert three-dimensional geometric data to VR, which poses many risks in terms of data loss and security.

TechViz is compatible with the most used engineering software of the market and with all existing XR displays. It can assess your technology ecosystem, your needs, and your budget to help you select the right hardware, 3D CAD software, and features for your company and your specific use cases.

As for the cost of the XR solution, it will be very dependent on your use case (hardware, software, and features). For instance, an immersive room is way more expensive than a pair of immersive virtual reality glasses, but offers very different results.

Which XR systems is TechViz compatible with?

You can run TechViz software in an immersive room, a powerwall, a head-mounted display (Oculus Rift, Meta Quest, HTC Vive focus 3, Varjo XR-3…) – or even a multi-device system.

You can view 3D CAD models from more than 200 application in TechViz without data conversion. TechViz software is the ideal solution if you want to interact with models from 3DEXPERIENCE in VR, CATIA in VR, PTC Creo in VR, NX in VR, Solidworks in VR, Revit in VR and many more.

Why should I choose TechViz for my AR/VR project?

TechViz is a leading augmented and virtual reality software editor since 2004, with a unique software that works without any data conversion. We have a strong expertise in the fields of virtual reality, 3D visualization solutions, virtual prototyping. We have a worldwide presence which helps us understand the specific needs of companies in other countries.

Questions?

More than 300 references chose TechViz worldwide

Contact us for more information on our VR software