A Case Study on integrating Virtual Reality and Secure Collaboration in Defense R&D and Crew Training.

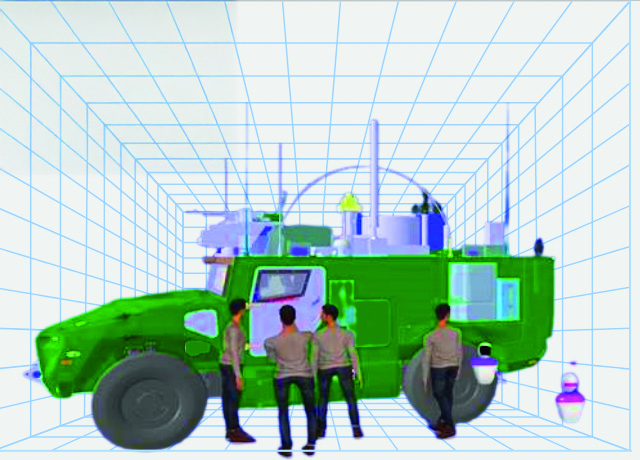

In this case study, we explore the integration of TechViz’s Virtual Reality technology by a leading European defense client to enhance its armored vehicle development process. Emphasizing non-physical prototyping for efficient design evaluation, the project showcases a secure, multi-user VR environment that allows for detailed, collaborative assessments of vehicle ergonomics and operability. This approach marks a significant advancement in defense R&D, combining cutting-edge technology with stringent data security.

1. Our Client and its Project

1.1. About our client

Our client is a major player in the European defense domain. Its missions include, but are not limited to, the testing and assessment of all equipment used by the military.

1.2. Our Client’s Project

Our client’s team was looking for a way to assess the operability and ergonomics of the armored vehicles they were developing, to ensure maximum usability for the crew. Since the vehicle was in the development stage and recreating it each time an adjustment was needed would have been costly and time-consuming, they sought a non-physical solution.

The obvious candidate for quick and adjustable testing was Virtual Reality. Thanks to the TechViz 3D-model-visualization solution’s compatibility with more than 200 CAD applications, professionals from a wide array of industries (including the defense one) can enjoy seamless conceptualization with models projected into any available XR system. Additionally, the zero-data-transfer visualization was a safe choice for such a sensitive sector as defense.

2. Challenges

2.1. Multi-user collaboration

Given that armored vehicles can transport up to six people, it was crucial for this number of people to immerse themselves in the virtual reality space. They needed to be able to see and interact with each other inside the VR.

2.2. Realism

- VR world (Ultra precision and near-zero latency): For tests in the Defense domain, conditions must be as close to real battlefield situations as possible. Thus, our client wanted to observe how the crew would enter, exit, and interact with the vehicle in real time. This required a tracking system that is both ultra precise and has a close-to-zero latency.

- Physical world: While ergonomics inside the vehicle (i.e., distance to gauges, controls, etc.) can be assessed using VR model visualization, other elements, notably, the speed of ingress/egress necessitate actual physical objects like exit ramps.

- Physical world – VR integration: The aforementioned objects had to be integrated into the VR space to offer a 100% realistic experience. Here, less crucial physical objects, which need fewer tests & adjustments and thus incur fewer R&D costs, should interact flawlessly with items of greater importance, requiring consistent improvements to achieve the best final product version.

3. Solution

TechViz accepted the challenge and created a multi-device XR environment tailored to its client’s specific needs. We created a multi-user space where a group of crew members (in our client’s case, six) can seamlessly interact with a model in real time, each from his or her perspective. We also enabled real-time interaction amongst them within the same virtual setting.

After the above-mentioned developments and modifications, our clients were virtually provided with a prototype of a military vehicle in which they could test various aspects ranging from ergonomics to operations in real-time.

We have taken into account the critical nature of our client’s domain and the necessity for ultimate data protection. Encrypting data is an effective method of safeguarding it. However, this only provides an “almost completely safe” data sharing. For data to be 100% secure, the team must have the capability to isolate itself from any external interaction (Further details on TechViz’s approach are available in the next section [Architecture]).

4. Architecture

TechViz’s distinctive architecture enables its clients to seclude themselves from the external world, thereby creating a leakage-free VR collaboration environment. This level of security is made possible thanks to a 100% on-premises model, where all necessary components are readily accessible. Wi-Fi serves solely as a substitute for cables.

For a better transparency on data handling in the TechViz collaboration, here are all of the elements involved in visualizing a 3D-model from any of the 200+ supported CAD applications:

- The 3D Model is opened in its native CAD application on the Master PC; NO Data Transfer occurs

- Each HMD is powered by one render PC, which, just like the Master PC, is located on the client’s site

- The content from the render PCs is streamed to the HMDs through a secure Wi-Fi channel (which serves as a cable replacement)

⇛ None of the components involves data sharing with the outside world. The sole wireless transmission happens on the client’s premises (Fig. 1: Secure VR Collaboration Schema).

Moreover, all streamed images are encrypted using VPN tunnelling.

5. Tracking System

To guarantee both precision and minimal latency in tracking, TechViz introduced a dual-tracking system.

To ensure a virtual space where interaction mirrors the real world as closely as possible, TechViz provides two distinct tracking systems:

- Absolute (global, “strategic” tracking of all users’ global locations within the virtual space). This tracking system allows to prevent and avoid any unintended collisions between users and with physical objects.

- Relative (user-centred) system that tracks the movements of each user thanks to motion sensors from TEA Ergo sensors attached to their limbs and equipment. This tracking system tracks the users’ interaction with the 3D model in real time to monitor collisions and to assess the operability and ergonomics of the vehicle.

Dividing the tracking system into two separate allows each of them to concentrate on its specific function, thus ensuring precision due to two different analyses, as well as minimal latency since the user-centred system is not burdened with global positioning tasks.

6. Conclusion

The collaboration with TechViz has provided our client with a state-of-the-art simulation facility, revolutionizing the evaluation and enhancement of armored vehicle operability.

The unique environment created by TechViz enables a full crew to engage in comprehensive testing within a meticulously crafted virtual space, supported by simple and easy-to-set-up physical elements.

This “Mixed Reality” solution has dramatically accelerated the R&D timeline, as iterative design modifications can be implemented and assessed virtually, bypassing the need for the costly and time-consuming physical prototypes previously used.

The innovative blend of virtual and physical testing elements has empowered our client to fine-tune vehicle designs with unprecedented speed and flexibility. The ability to rapidly prototype in the virtual space, combined with the capacity to test critical physical elements like exit ramps for ingress and egress, has ensured that future armored vehicles are optimized for field performance.

The secure, on-premises data environment has ensured that sensitive information remains confined within the client’s premises.

In summary, our client now possesses the capability to simulate and evaluate virtually every aspect of vehicle design. This has led to a significant improvement in the development of operation-ready and ergonomic armored vehicles, which is invaluable in a reality where conflicts can arise overnight and where every second counts.