Mazagon Dock Shipbuilders Limited (MDL) is India’s largest naval shipbuilder. Based in Mumbai, MDL is known for constructing warships and submarines for the Indian Navy. With the increased complexity of modern naval ships, coupled with challenges like limited space and intricate arrangements, MDL’s design & production teams had been struggling with severe project delays & cost overruns.

In 2011, MDL discovered the benefits of virtual reality to improve their design process and modernize shipbuilding. By 2019, they fully committed to adopting this technology, aiming to transform their methods and set a new direction for ship construction.

1. Challenges in the High Seas of Warship Construction

Building warships is a complicated process that often leads to long delays and increased costs. Here’s why:

Design Complexity:

MDL faces major challenges when designing warships. A single 150-meter ship may require fitting 15 km of pipes, 6 km of ventilation, plus over 13,000 pieces of equipment. This demands extremely precise planning in a very limited space. These constraints slow down the design phase, and many issues are only discovered later during customer reviews, resulting in rework. As one MDL representative said: “The design should have highly accurate data and should be perfect, checked at all times. In any situation, be it during warship operations or other scenarios, the design must not fail. This is an absolute requirement.”

Slow Approval Process:

The Navy uses a traditional design approval method called line-out inspections (LOIs). Construction must pause until drawings are validated, which often causes major bottlenecks, a point we’ll explore later.

Rework During Construction:

Because of the complexity and constant need to integrate multiple systems, rework is common once construction begins. Long delivery times also mean that equipment designs sometimes change before installation, and even a minor adjustment can impact other tightly packed components.

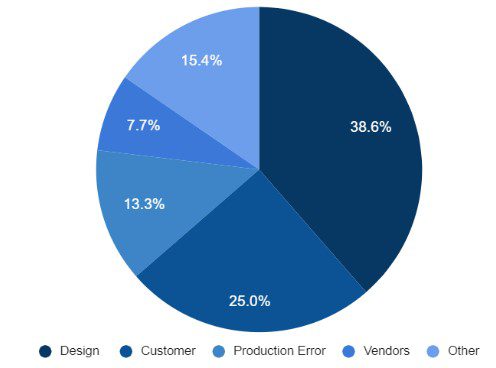

Rework has always been a challenge in shipbuilding, and the chart below highlights the most common causes across multiple projects.

2. Decoding LOI: Charting the Shipbuilding Course

In warship construction, Line Out Inspection (LOI) was a key approval stage. It was a long-established part of the workflow. Here is how the process worked:

1. 3D CAD Model Preparation

The first step was creating a detailed 3D CAD model. Multiple teams worked together to avoid rework later in production, using tools like AVEVA Marine and CATIA.

2. Production Drawings

From the 3D model, several 2D layout drawings were produced for each compartment, usually at a 1:20 scale, and sent to the workshop.

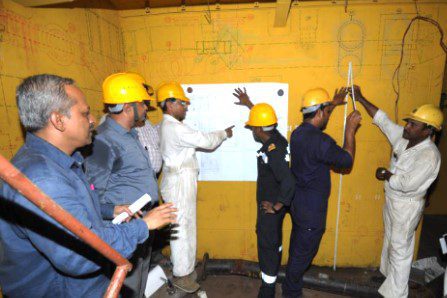

3. Line Out Inspection (LOI)

Before installing any equipment, the production team translated the 2D drawings onto the actual compartment by marking every component on all six surfaces. This step verified two main points:

- Fit and interference: Everything needed to fit without clashes.

- Ergonomics and maintenance: Crew movement and equipment access had to remain practical.

According to MDL, this phase involved many discussions, revisions, and updates until the final layout was approved. Only then were drawings released for production.

However, LOI came with major challenges:

- Very slow progress: Completing LOI for 7–10 compartments took about a month, with roughly two revisions each. For a ship with 395 compartments, this alone could stretch to almost seven years.

- Costly physical mockups: Important areas like the engine room or bridge often required life-size mockups, which were expensive and time-consuming to build.

- High rework rates: Without a complete view of space constraints and crew movement, many issues were only discovered during construction, causing additional rework and delays.

As MDL explained, they could resolve only about 10 out of 100 design issues during LOI, meaning most minor problems remained and were carried into the final ship.

3. VR Technology to the Rescue

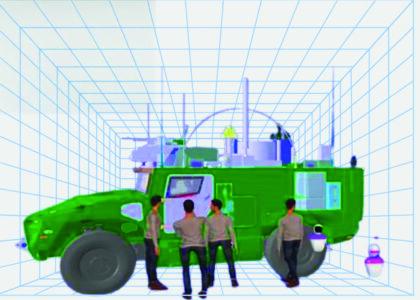

In the middle of these difficulties, MDL’s design teams saw VR as a potential solution. By viewing the 3D CAD model in virtual reality at a true 1:1 scale, they believed they could spot problems earlier in the design phase. Once this process worked for the first ship, it could then be reused for sister ships, saving both time and cost.

VR offered a new way to handle the LOI process:

- Full-scale visualization: VR makes it possible to view the ship model at real size, removing the need for expensive physical mockups.

- Better design validation: Digital tools in VR allow accurate measurements, collision checks, and review of access and movement.

- Faster changes and lower cost: Design updates can be implemented quickly based on feedback, avoiding long and costly rework later.

However, the transition was not immediate. Even with the clear potential for time and cost reduction, adopting VR faced several obstacles. Long-standing habits and traditional methods were deeply embedded in the workflow, and overcoming them required effort and change. The question then became: what were these barriers, and how did MDL plan to break through them?

3. Transformation of warship design processes

With the introduction of VR technology, MDL embarked on a transformative journey and achieved significant results:

- Immersive Visualization: Designers could view warship designs in 3D, helping them make better decisions and spot potential improvements.

- Optimized Space Use: VR-assisted reviews improved the arrangement of complex systems and equipment.

- Virtual Prototyping: Reliance on physical models was reduced, speeding up design validation.

- Better Collaboration: Teams and stakeholders could review designs together in real time.

- Faster Approvals: Interactive virtual models accelerated the design approval process.

- Reduced LOI Time: Line Out Inspections became much quicker, boosting efficiency.

- Smoother Production Coordination: Communication between design and production improved, increasing overall efficiency.

The impact was substantial, both qualitatively and quantitatively. By using VR for LOIs, MDL cut project timelines dramatically. For the P15A project, the first to adopt VR, subsequent ships saw over 21 months saved compared to the first-in-class ship. Further reductions followed: 23 months for P15B and 18 months for P17A. Overall, this added up to 62 months saved across these projects, demonstrating the powerful benefits of combining VR with refined business processes.

4. Conclusion - Future for the shipbuilding industry

he adoption of VR technology has transformed shipbuilding at MDL. By leveraging virtual reality, MDL overcame the challenges of warship design and delivered highly precise vessels. Their focus on innovation and advanced technology has strengthened India’s position in maritime defense. Looking ahead, MDL continues to lead the industry with its commitment to excellence and forward-thinking approach, shaping the future of naval shipbuilding.

About Mazagon Dock Shipbuilders Limited (MDL):

MDL has a long history of shipbuilding excellence and has played a key role in enhancing India’s naval capabilities. As a leading public sector shipyard, it is recognized for innovation, skilled craftsmanship, and high-quality standards. MDL has delivered advanced naval vessels and submarines, contributing significantly to India’s maritime strength. Beyond warships, the shipyard produces technologically sophisticated support vessels, reinforcing India’s self-reliance in naval defense. With a strong focus on continuous improvement and indigenous technologies, MDL remains a cornerstone of India’s shipbuilding industry.