Welcome to TechViz’s dedicated page for the Shipbuilding industry, where advanced VR solutions meet the complex demands of marine design, construction, and maintenance. By integrating VR and AR into every stage of the shipbuilding process, TechViz helps companies enhance design accuracy, streamline collaboration, and improve safety and efficiency. From conceptual design to on-site maintenance, discover how TechViz’s immersive tools are driving innovation and operational excellence in the shipbuilding industry.

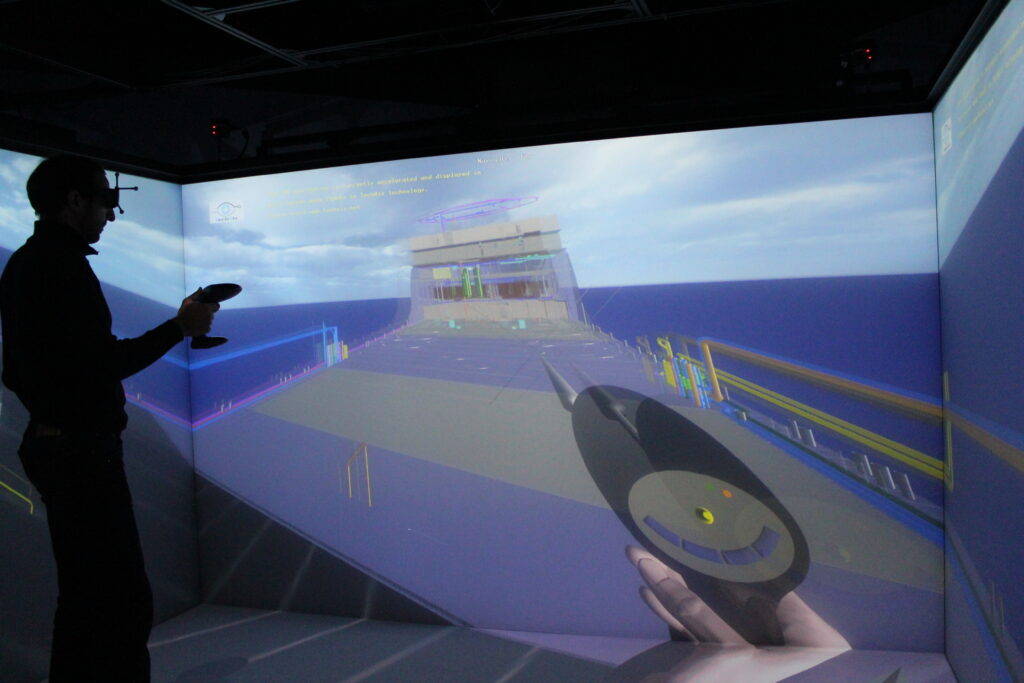

The shipbuilding industry is embracing VR and AR technologies to meet the demands of complex designs, rigorous safety standards, and the high costs of production. With VR, designers, engineers, and operators can visualize large-scale ship models, perform virtual walkthroughs, and address potential issues before construction begins. TechViz’s solutions enable shipbuilders to improve planning precision, accelerate project timelines, and minimize costly errors, ensuring a smoother transition from design to sea-ready vessels.

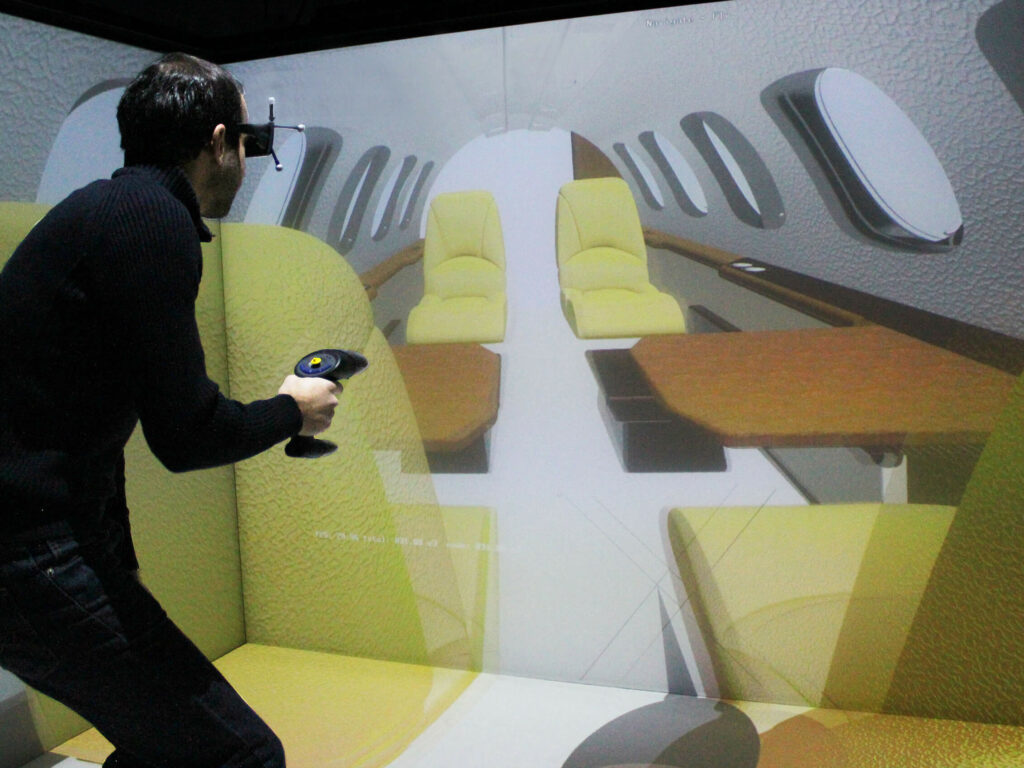

VR enables 3D visualization of ship designs, allowing engineers to detect and resolve design flaws early in the process. This leads to better decision-making, reduced rework, and significant cost savings throughout the production lifecycle.

VR and AR tools allow teams across different locations to collaborate on complex designs in real-time, sharing insights and making adjustments quickly. This remote accessibility speeds up decision-making and reduces travel costs.

VR training programs provide crews with realistic simulations of vessel operations and emergency procedures, enabling them to gain hands-on experience in a safe environment, which improves preparedness and reduces training costs.

AR headsets allow technicians to access real-time maintenance data and overlay instructions directly onto machinery, enabling quicker repairs and reducing vessel downtime, which is critical in the shipbuilding industry.

VR simulation tools allow project managers to test and plan construction phases in a virtual environment, ensuring optimal resource allocation, preventing delays, and maximizing efficiency from start to finish.

TechViz’s core technology seamlessly integrates with over 200 3D applications without requiring data conversion, including industry-specific software like AVEVA, CADMATIC, and Siemens NX. This direct integration allows shipbuilders to visualize and interact with complex 3D models in real-time, enhancing precision and collaboration at every stage of the design and build process.

Train crews using VR simulations of shipboard operations, safety protocols, and emergency scenarios, ensuring they are prepared to handle real-life situations safely and effectively.

Use VR to view and refine detailed designs created in AVEVA or Siemens NX, enabling stakeholders to conduct virtual walkthroughs, detect issues, and optimize designs before production.

Enable design and engineering teams across global locations to collaborate on ship models in real-time, ensuring alignment, facilitating quicker decision-making, and reducing the need for physical model inspections.

Equip technicians with AR headsets to receive step-by-step maintenance instructions overlaid onto equipment, streamlining repairs and reducing time spent in dry dock.

Plan and test different construction phases in VR, from hull assembly to equipment installation, ensuring optimal resource allocation and minimizing costly delays.

TechViz’s immersive VR solutions bring a new level of precision, safety, and efficiency to the shipbuilding industry, supporting every stage of the vessel lifecycle from design to deployment. Explore how TechViz can help your team elevate productivity, reduce costs, and deliver high-quality vessels ready for the demands of the open sea.