Welcome to TechViz’s dedicated page for the Industry & Manufacturing sector, where innovative VR solutions meet the challenges of modern manufacturing. By integrating VR and AR into design, production, and quality control, TechViz empowers companies to streamline processes, improve team collaboration, and enhance product quality. From prototyping to factory floor training, our immersive tools drive operational efficiency and precision across the entire manufacturing lifecycle. Discover how TechViz is revolutionizing Industry & Manufacturing with cutting-edge immersive solutions.

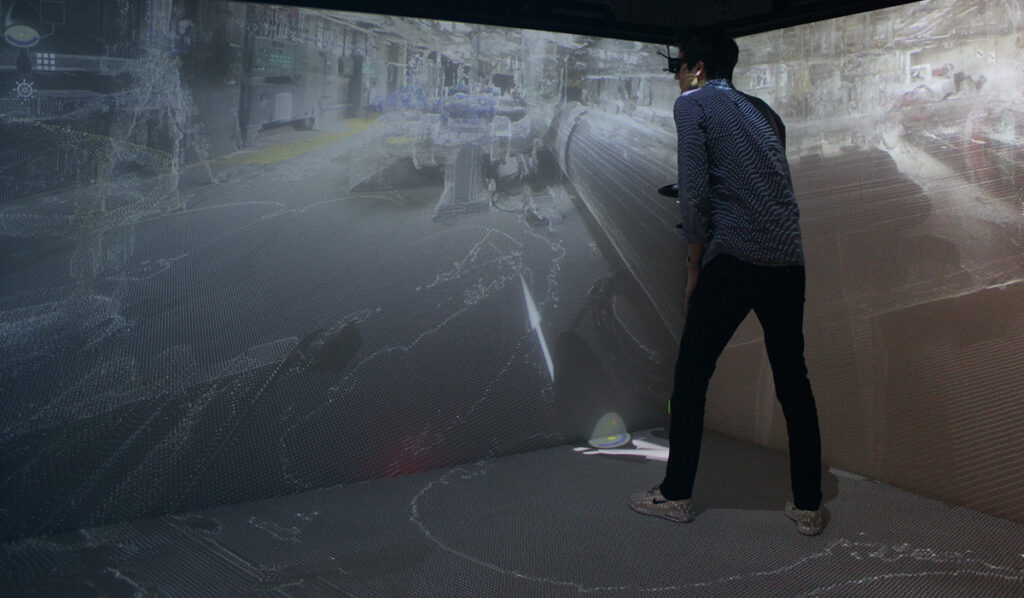

The Industry & Manufacturing sector is rapidly evolving, and VR and AR technologies are at the forefront of this transformation. TechViz’s solutions enable manufacturers to visualize complex 3D designs, simulate production lines, and optimize workflows—all within an immersive virtual environment. These tools reduce the time and costs associated with physical prototyping, improve team collaboration across sites, and enhance safety protocols, driving greater productivity and quality in every stage of manufacturing.

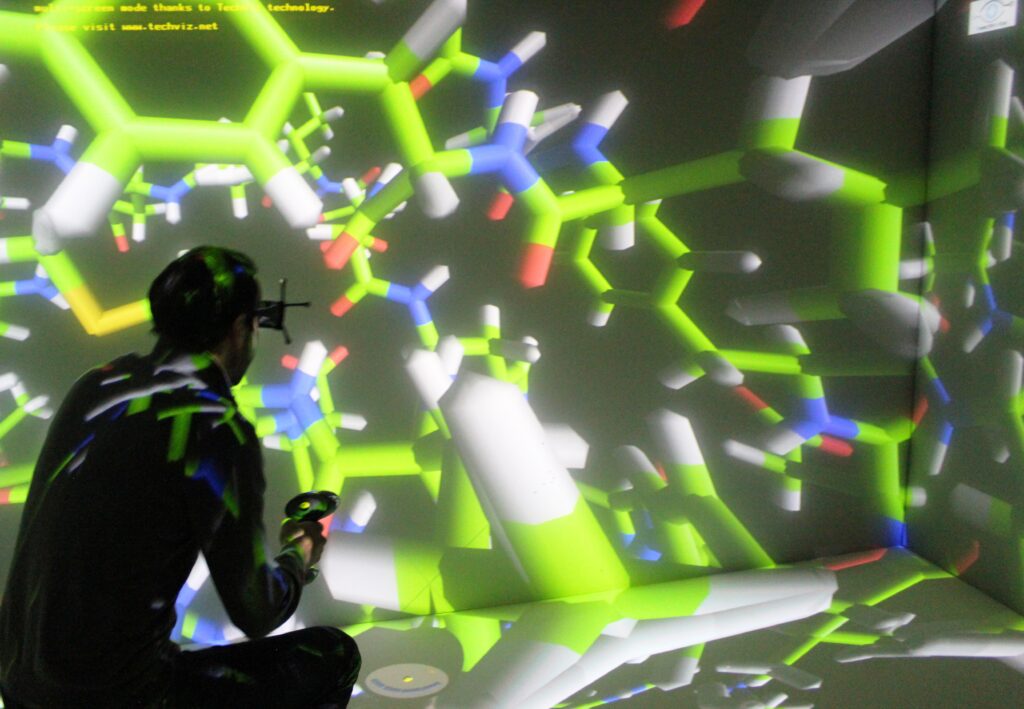

VR enables early 3D visualization of products, allowing engineers to identify and resolve design issues before physical prototyping. This results in faster product development and significant cost savings.

VR and AR allow global teams to collaborate on product designs in real-time, making it easy to share updates, provide feedback, and implement changes immediately—without the need for travel or physical prototypes.

VR-based training immerses employees in simulated factory environments, improving safety awareness and skills acquisition. This method is proven to enhance retention and reduce on-the-job accidents.

AR headsets enable technicians to access real-time diagnostic data and maintenance instructions directly on machinery, speeding up repair times and reducing equipment downtime.

VR allows manufacturers to simulate and test production lines in a virtual environment, optimizing resource allocation, identifying bottlenecks, and ensuring that facilities are set up for maximum efficiency.

TechViz’s core technology integrates seamlessly with over 200 3D applications without data conversion, supporting widely used tools such as Siemens NX, Autodesk Inventor, and CATIA. This compatibility allows manufacturers to visualize, test, and interact with complex designs in real-time, enhancing precision and streamlining processes from design to production.

Plan and test factory layouts and workflows in a VR environment, ensuring efficient production line setups and minimizing potential bottlenecks.

Use VR to visualize detailed product models from CAD software like Siemens NX or CATIA, enabling thorough design reviews, modifications, and improvements before prototyping.

Provide employees with VR training simulations to learn factory procedures, safety protocols, and equipment handling in a risk-free environment, improving skills and reducing accidents.

Use VR to visualize and test different production processes, identify areas for improvement, and ensure high quality and consistency across production runs.

Enable on-site technicians to use AR for real-time guidance from remote experts, helping diagnose and repair equipment faster, which minimizes production downtime.

TechViz’s immersive VR and AR solutions empower Industry & Manufacturing by enhancing design accuracy, operational efficiency, and safety standards. From product development to workforce training, our technology supports every stage of manufacturing, driving productivity and innovation. Discover how TechViz can help your team meet the demands of modern manufacturing with unparalleled precision and efficiency.