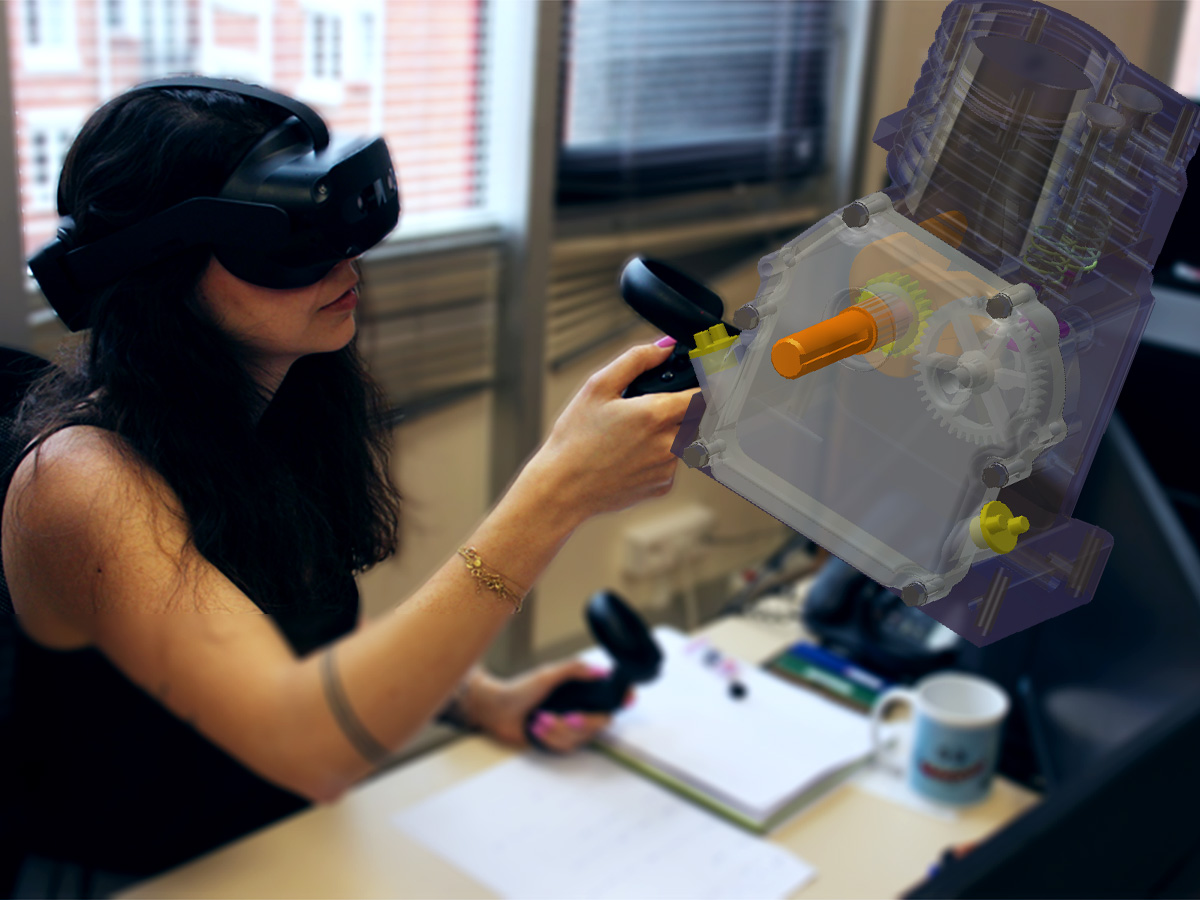

Virtual assembly: move parts and detect collisions in 3D models

Assembly process account for a large part of time and cost of product development. A virtual manufacturing simulation system enables companies to better analyze product designs and gather 3D collision feedback.

Select, move and manipulate parts of your 3D model

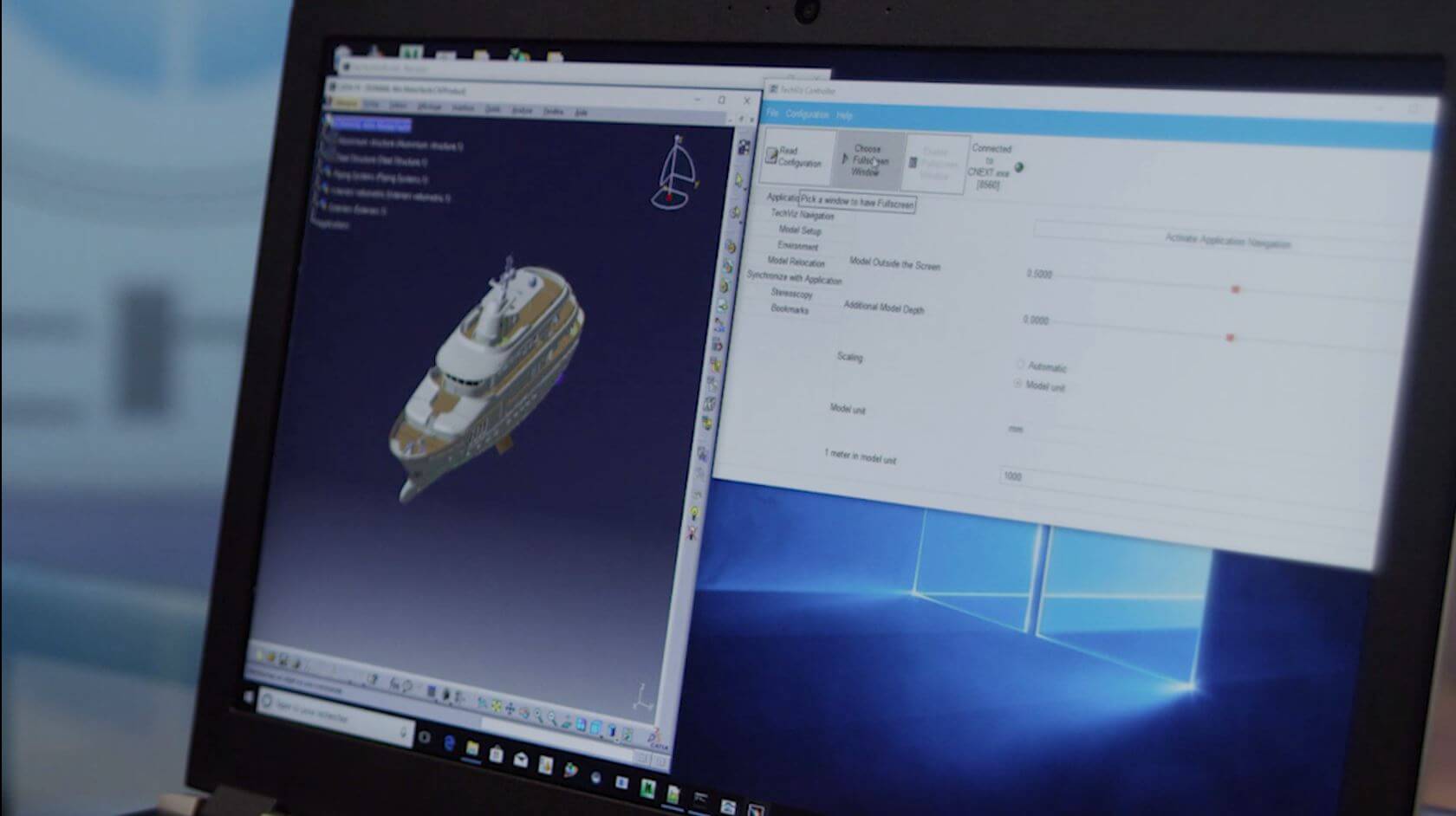

The Move Parts feature in TechViz Virtual Assembly has a universal part recognition engine that allows part selection and manipulation. Application connectors like CATIA Connector, Navisworks Connector, NX connector, Creo parametric Connector, used in addition to the Virtual Assembly feature provide part tree and metadata information for each part in the 3D CAD model, as they are defined in the PLM database.

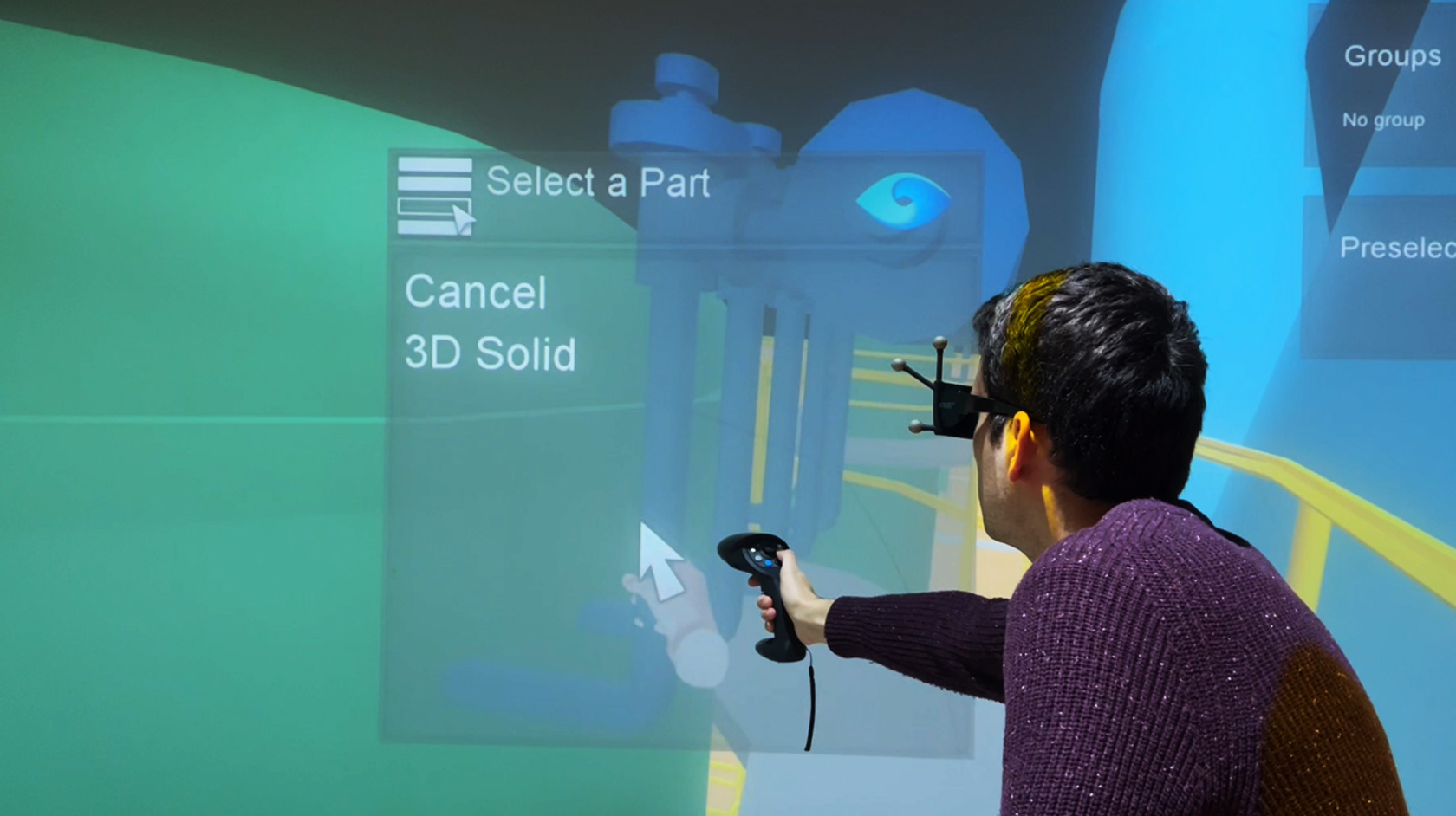

TechViz proposes several exploration types and selection instruments:

- Root-to-Leaf exploration (Top-Down Analysis): This quick glance approach is key to understanding what the model looks like (in 1:1 scale) as well as how its parts are connected within a 3D virtual space. It helps users instantly get an idea of the general layout and dimensions of the model, which is critical for understanding complex designs.In VR, this method is particularly effective for spotting overall design patterns and ensuring the structural coherence of the model. It’s also useful during team reviews, allowing for a collective focus on the broader design aspects before examining finer details.

This method supports strategic planning by providing a clear view of the model’s main components and their relationships.

- Leaf-to-Root exploration (Bottom-Up Analysis): This approach focuses on the details first and allows for a profound examination of individual parts, making it ideal for quality control and detailed inspections.

Particularly useful for identifying issues or optimizations at the component level (e.g., fitment, ergonomics, aesthetic details) that might not be apparent from a broader perspective. It helps in ensuring that every detail is in alignment with the overall design objectives.

For the design review, it may be used with specialized teams or employees responsible for specific aspects of the design process.Select Part to show its information using the virtual hand for a super-precise inspection or laser for a quicker inspection.

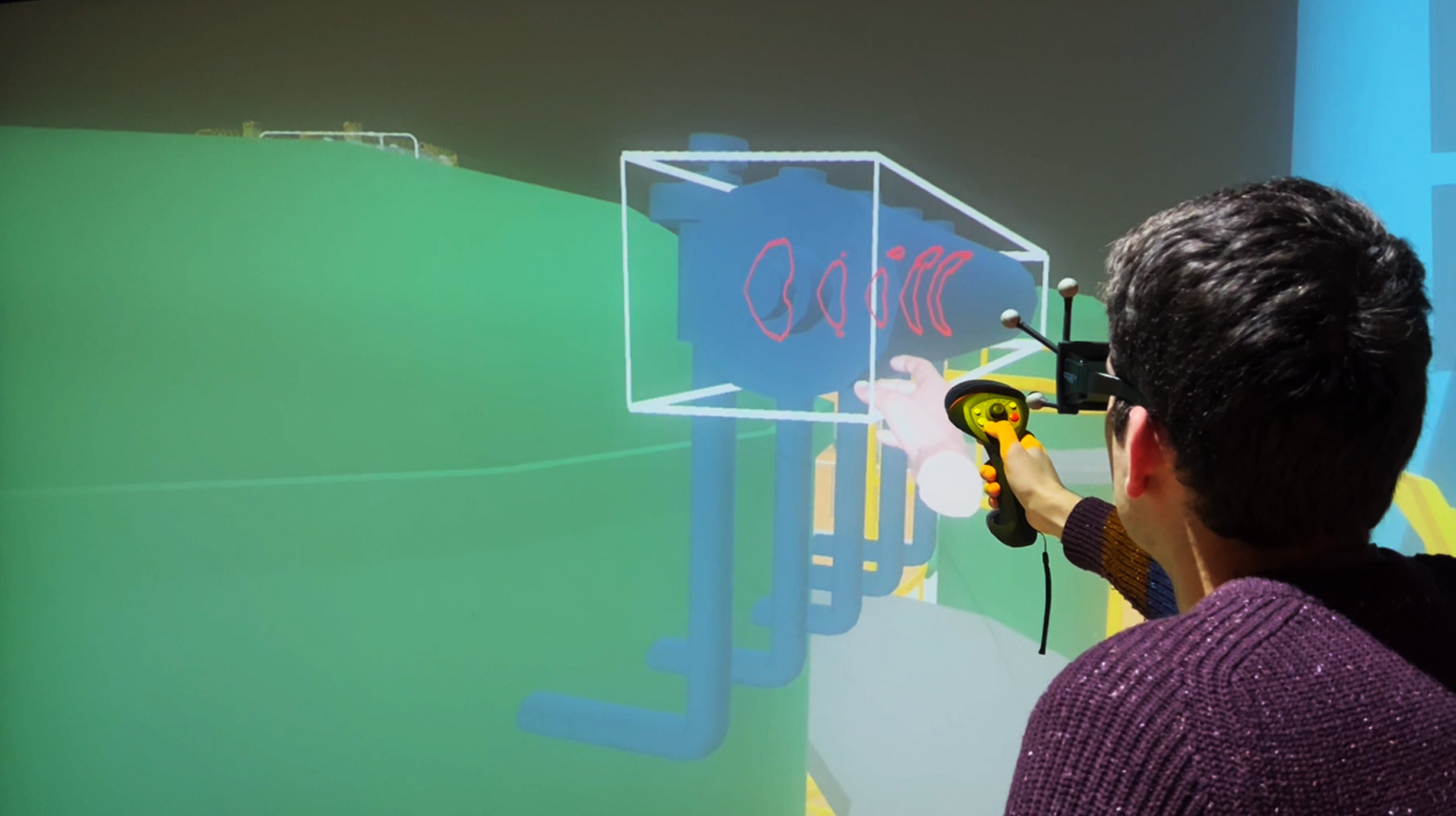

Detect collisions and clash of parts of virtual objects

The Virtual Assembly feature uses triangle to triangle intersection to detect 3D collisions. It allows users to detect that virtual objects have intersected and even recorded a path with the different collision points to be reloaded for further studies. An ideal solution for project reviews, maintenance, and training sessions.

Simulate collisions with real physics

Virtual Assembly simulates the clash between parts thanks to the IPSI connector (Interactive Physics Simulation Interface). The IPSI engine is the only technology on the market today able to carry out real-like simulation with large CAD models. This feature guarantees the non-interpenetration of objects, and triggers visual feedback for physic simulation and even haptic feedbacks when the collision occurs.

How does virtual assembly work?

1

Load your 3D model in your CAD software and display it with TechViz

2

Select Virtual assembly, divide your CAD model in groups and move the different 3D parts

3

Detect and simulate collisions to see if the parts clash

During the design phase of product development, before any physical prototype is created, tracking technologies empowers you to intuitively simulate the assembly process (and feel with haptics). And our software is fully compatible with Human Body Tracking devices (TEA, ART, Xsens, TeslaSuit…).

Use cases

Visualize your CAD model in VR to validate mounting and unmounting tasks and take mechanical constraints into account

Make fixability tests, to see if the repair tools can be used in confined spaces

Check if an equipment can be fitted inside and manipulated without interfering with the factory’s structure

See what parts of the 3D model can be reached from a precise position

Reduce the need for physical prototypes by performing motion simulation and stress analysis on mechanism components

Apprehend how to use 3D modelling in a virtual environment.

A virtual and interactive experience

A real driver for immersive simulation, Virtual Assembly works directly from your native 3D application in real time. Compatible with more than 200 3D software (Catia, 3DExperience, Navisworks, Creo, Solidworks, Unity, NX, Vred, …), our VR software solution enables an interactive experience by simulating physical interaction of objects in 3D. Ideal to improve assembly processes, validate maintenance operations or reduce technical risks.

Benefits of Virtual Assembly manufacturing

- Move interactively a part of the model or a virtual tool:

- Fine displacement step by step

- Display part position and orientation

- Multiple parts of a 3D model can be moved and grouped together

- Associate parts with tracked target

- Select an object and define a constraint

- See collisions and record a path that can be reloaded for further studies

- Connect to the PLM Product Structure tree (for supported 3D applications)

Bring your collision simulation further with Haption haptics toolkit

TechViz IPSI Connector integrates Haption Interactive Physics Simulation Interface haptic arm into our software, which enables users to interact with the thee-dimensional visualization for an immersive and complete interactive experience in Virtual Reality. This makes your haptic system and/or software compatible with your 3D CAD model. Adding haptic rendering to Virtual Assembly provides very efficient feedbacks for collision simulation.

Advantages of combining IPSI’s haptic arm with TechViz software:

- Based on Haption IPSI industrial engine

- Displayed by TechViz with the IPSI Connector

- Parts follow rigorous physics simulation

- Full rigid body engine

- Visualization of forces

Possible to use another force-feedback device (Virtuose, Inca, and Able)

Questions?

More than 300 references chose TechViz worldwide

Contact us for more information on our VR software